The WTP (heat exchanging plates) system is a tempering concept which serves as an economical alternative to conventional chemical devices such as the half-tube coil and double-jacket. Compared with these two designs, the WTP- system® offers a large number of advantages:

- Lower purchase price

- Lower operational costs

- Better heat transfer

- Faster heating

- Better control characteristics

- More efficient utilization of the heat transfer medium

- The performance of existing installations can be raised without the need for additional space

- Supply lines and pumps can have smaller dimensions

- Complex geometries are possible

- All installation positions are possible

- Lower weight

- Connectors can be retrofitted easily

- Clamping plates can be retrofitted

- Ideal for flat surfaces

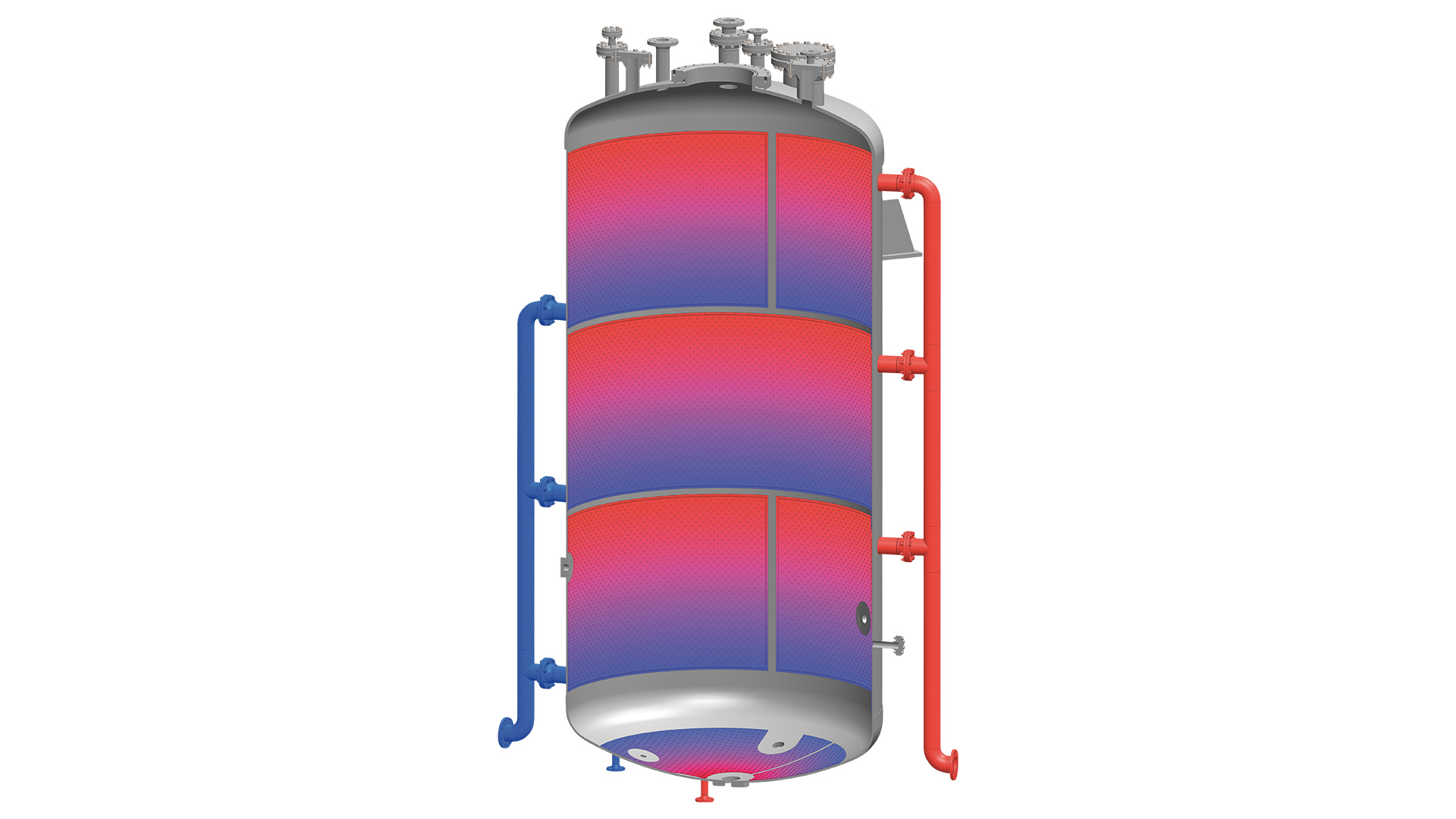

WTP-system® on the inside area

WTP-system® on the inside areaAs the WTP-heating system is not designed on any mathematical principle and used preferentially for installations which operate in accordance with DGRL, destructive testing is used in this case. The samples, which are identical with finished parts in terms of shape and welding pattern, must meet the following criteria:

In accordance with DGRL, each sample must withstand 5 times the excess operating pressure, multiplied by the k-value at the room temperature and divided by the k-value at operating temperature. The ASME code requires the system to withstand 6 times the excess operating pressure. Calculations for a pressure vessel designed in accordance with DGRL and equipped with a WTP-system® need not take this system into account. Due to the smaller flow cross section, which is smaller than the cross section of a pipe DN100, the WTP-system® is assigned to DGRL category 1, in accordance with diagram 6 or diagram 4. The tests are carried out due to modul A, which states that no more future tests will be needed.

The bursting behaviour of the WTP-system® is interesting in this context. If the system bursts, only one or two welding rings are affected (Figure 1), thus permitting repairs to be performed easily. Investigations of samples after bursting do not reveal cracks in adjoining welding rings or other alterations in the microfinish. Connectors can also be retrofitted (Figure 2).

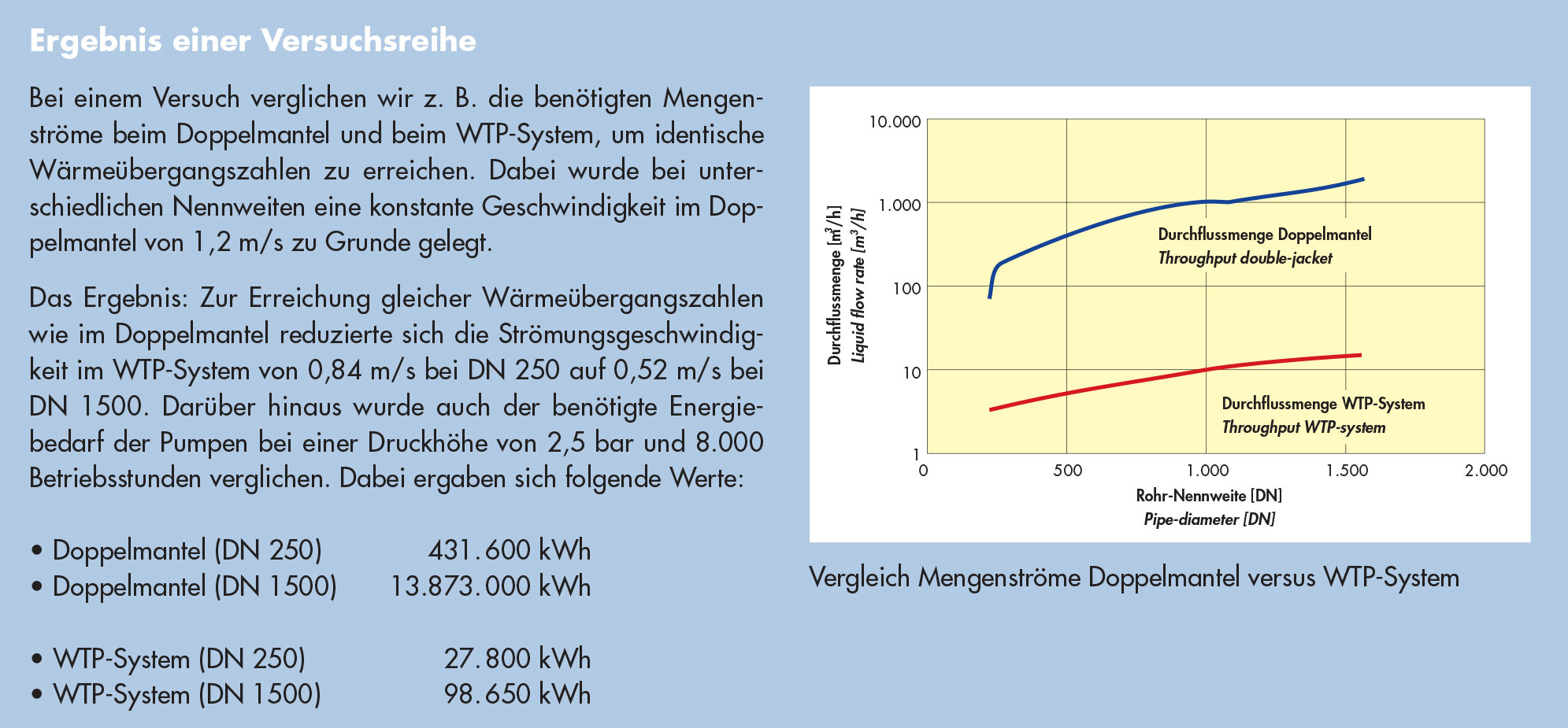

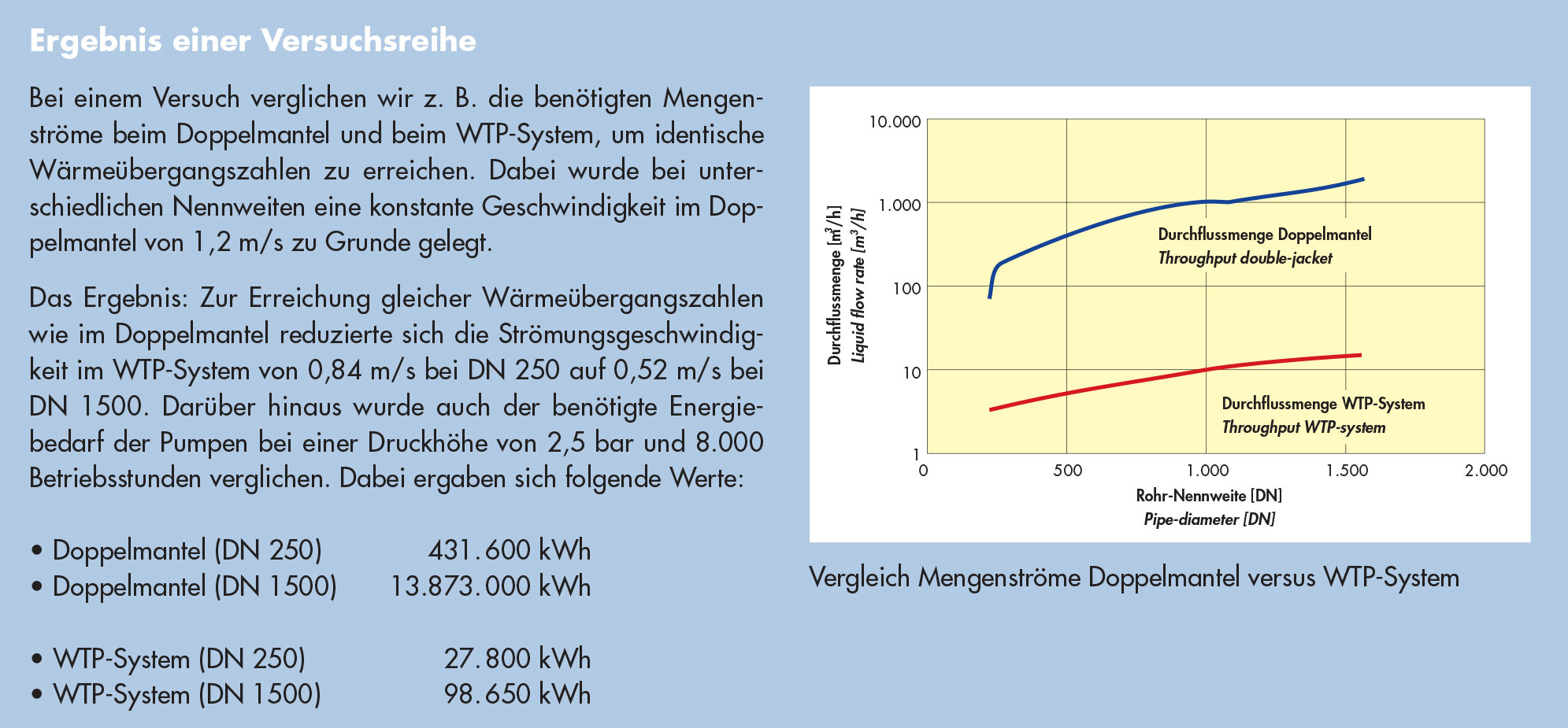

WTP-System® and double jacket comparison

WTP-System® and double jacket comparisonDuring a series of tests involving an application of steam, we were able to achieve values of up to 5,000 W/(m2 K) by appropriately distributing the steam and condensate connectors. The heat chart specifies values of between 1,100 and 1,600 W/(m2 K) for half-tube coils. This means that the heat transfer coefficient here is 50 % higher than that of half-tube coils; naturally, this also influences the heating period and, consequently, the efficiency.

This proves especially important for existing installations, from which the performance can be increased without the need for spatial modification by replacing vessels possessing a conventional heating system with vessels possessing a WTP-system®. As this system is able to achieve turbulent flows at a very early stage, the quantity of heat transfer medium it requires is thus also notably low. As a result, the dimensions of supply lines and pumps can be reduced. Due to its low volume, the WTP-system® also exhibits excellent control characteristics.

As regards retrofitting: Existing vessels can be retrofitted with the WTP-system® by attaching clamping plates (see photos below). Heat transfer can then be improved by applying heat-conducting cement. However, the heat transfer coefficient of a WTP-system® configured in this manner is not ideal, rather suitable mainly for a certain temperature level.

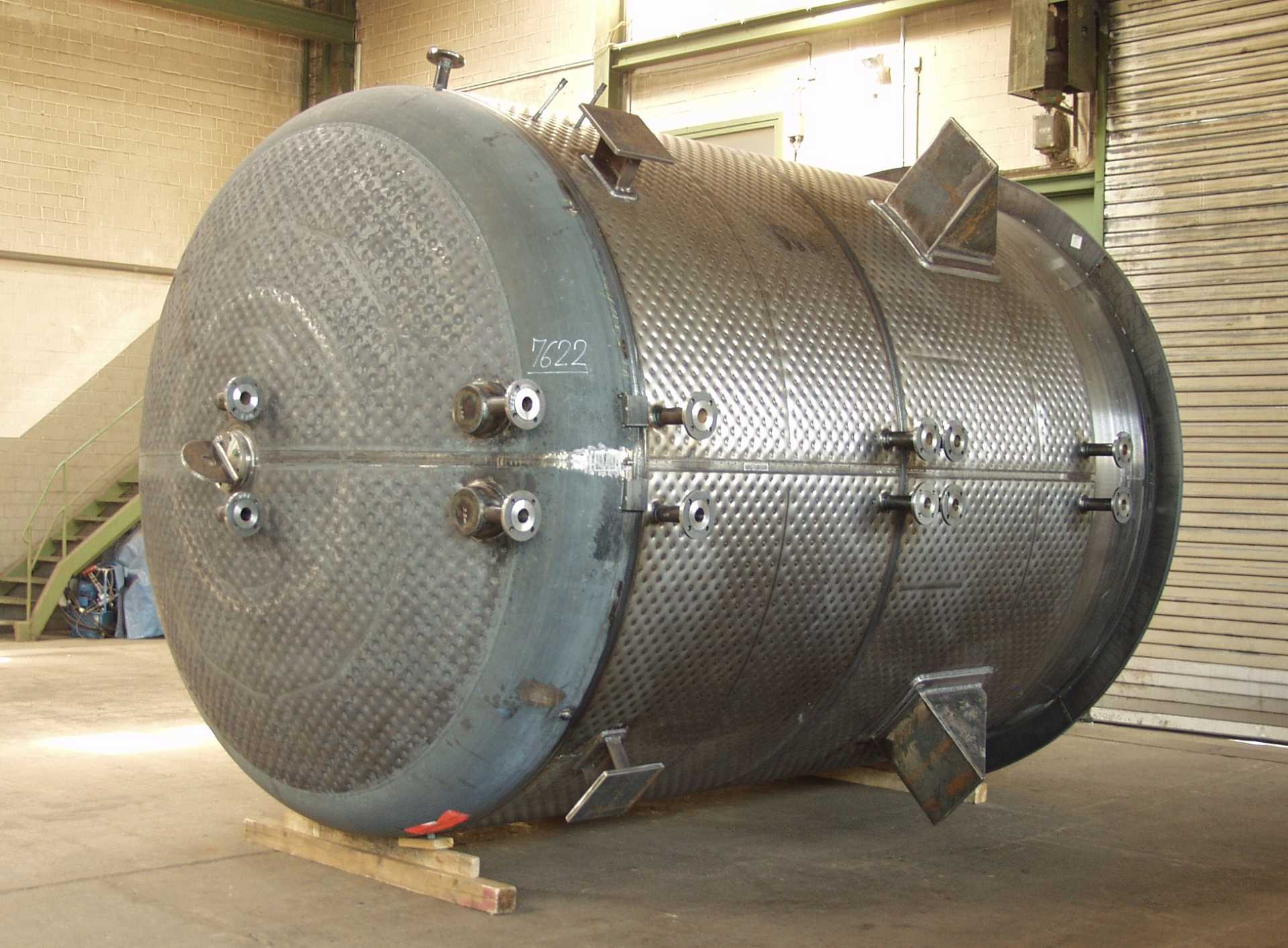

WTP-test vessel, inner surface/outer surface with WTP-system

WTP-test vessel, inner surface/outer surface with WTP-system