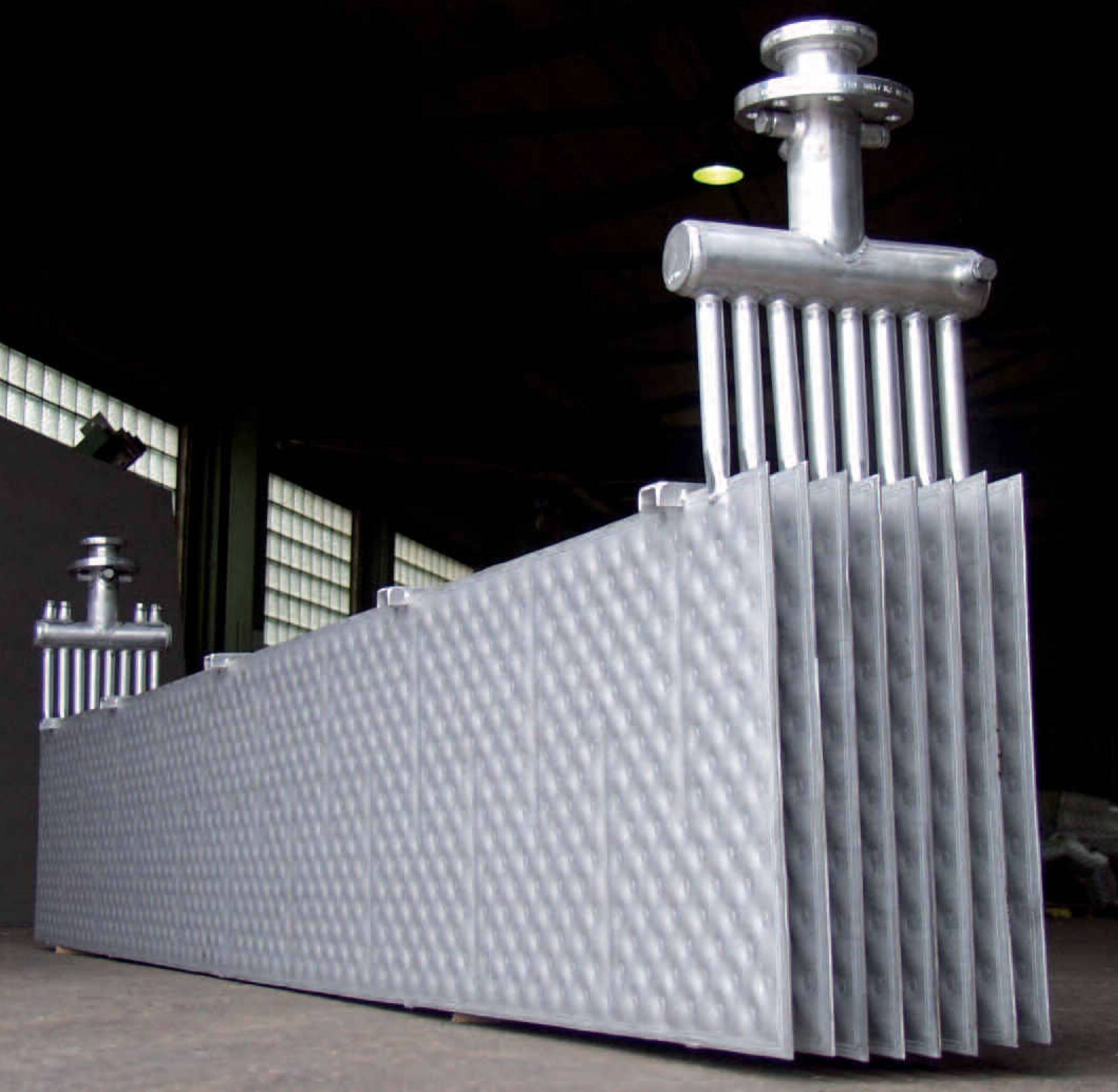

WTP-Liquid-Liquid Heat Exchanger

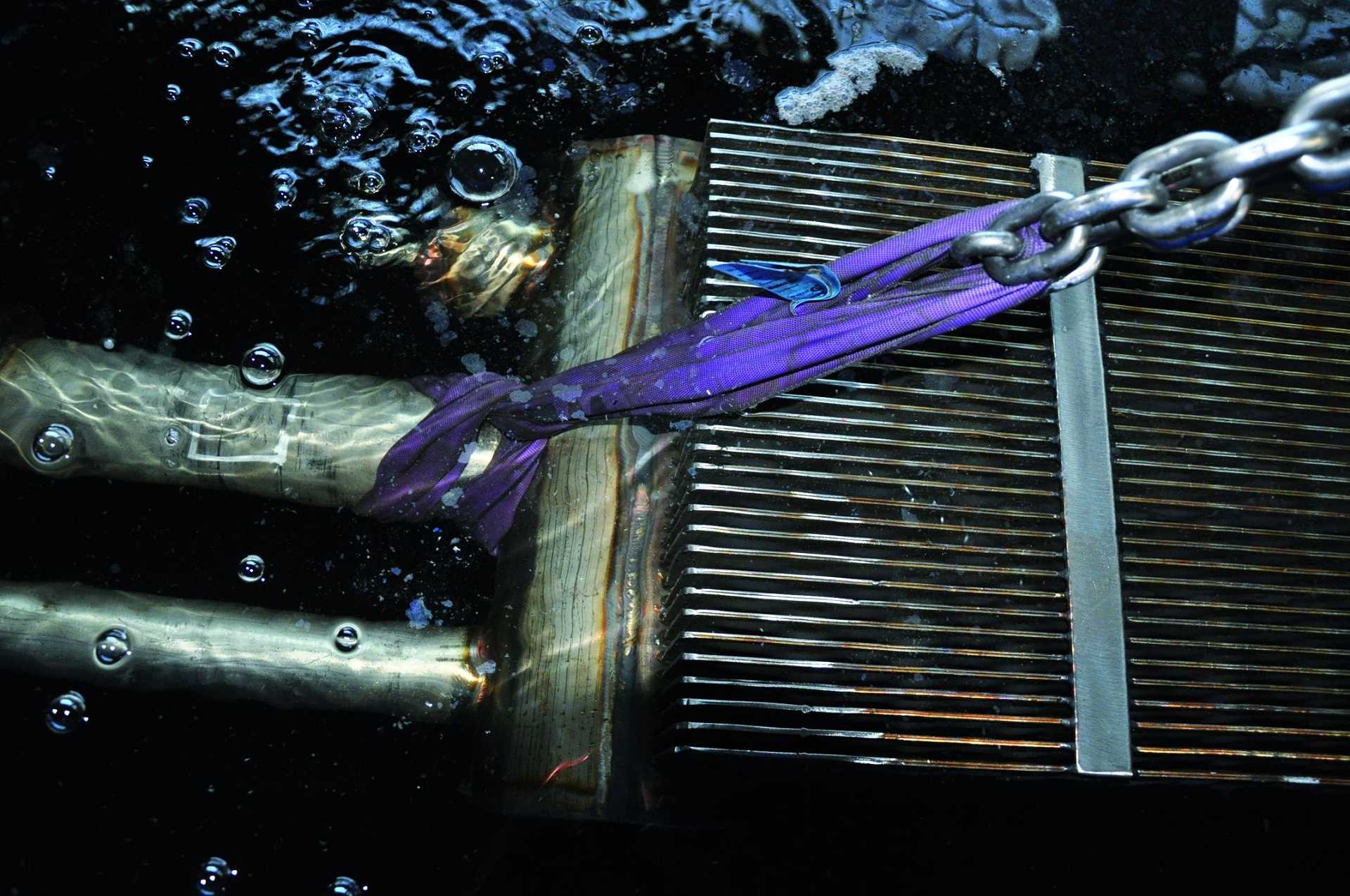

WTP plates are particularly suitable for the heat transfer of process water at stagnant or flowing waters. Conditioned process water is led into the plates for cooling or heating. The waste water or river water is located on the outside of the plate pack. This prevents contamination in the WTP plates. “Fouling” on the smooth outside of the WTP plates is largely prevented by the flow of the flowing water or can be easily cleaned off by the open access to the outside of the plate by means of a steam jet. The WTP plate package can be installed directly into a river course, separate flow channel or waste water basin.

Compared to tube bundles, longitudinally-flowed WTP plates are more cost-effective to install and operate for the same transmission capacities. The pressure drop on the process side can be adjusted by expanding the WTP plates and selecting the grid. In extensive test series LOB has measured the pressure losses in the plates as a function of the inlet channels, the expansion of the honeycombs/cushions and the process water volume and recorded them in calculation models. The velocities in the inflowing water are usually in a range from 0 m/s in standing water to 1.2 m/s in flowing water. In the latter case, free convection is overlaid by forced flow. The mixed convection generated in this way results in higher heat outputs. In the application example, the calculated heat output for a flow surface of approx. 35 m² and for free convection on the outside of the plate pack was approx. 700 kW. The heat transfer values in this operating mode are about 600 to 800 W/(m²K).

Depending on the application, the performance data can be extended by the number of plates and the length of the run by connecting them in series. Feeding on the cooling water side can also be done via a distribution beam. The pressure loss in the plate can be adjusted by expanding the WTP plates.