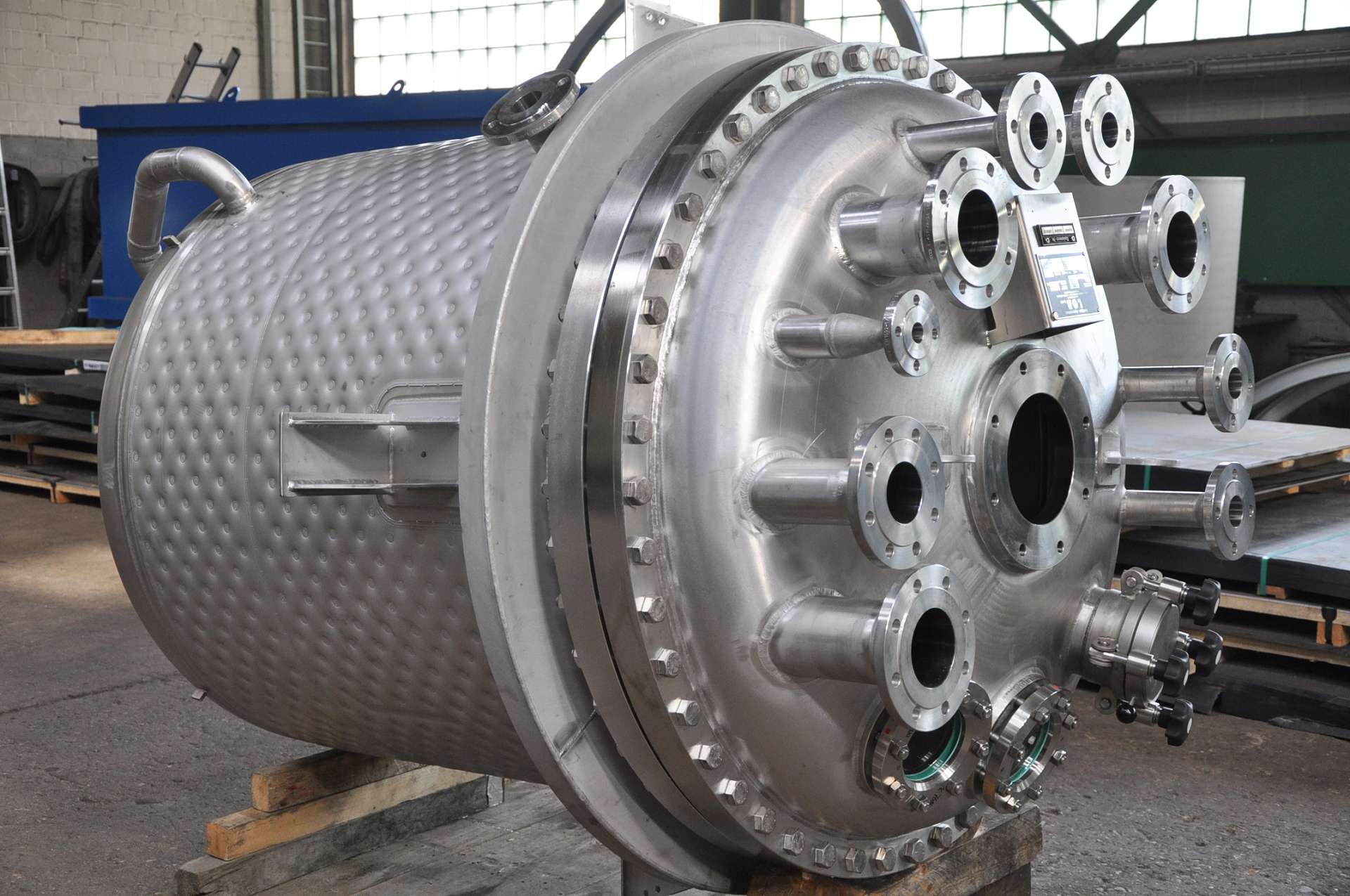

Agitator vessels including Testrun and CE-certificate of the machine

Agitator vessels can be built by us in all possible sizes and materials – a complete overview of materials can be found here.

Agitator vessels with WTP as vessel heating The LOB WTP System® is an alternative to conventional systems such as half-pipe coil or double jacket for the use of agitator vessels. The advantages are both the effective heat transfer and the low manufacturing costs. The heat transfer at agitator vessels and thus the energetic efficiency is determined by the heat transfer inside the vessel and on the outer wall as well as by the wall thickness of the vessel. The heat transfer at the inner wall of an agitator vessel is essentially dependent on the shape of the agitator (e.g. spiral agitator, blade agitator), speed of rotation, vessel and agitator dimensions and the material data of the vessel contents. The heat transfers α inside the inner wall of the vessel are usually in the same bandwidth as the heat transfers in the WTP jacket. To determine the heat transfer inside, please refer to the agitator manufacturers and operators of agitator vessels.

However, high α values on the outer wall are accompanied by higher pressure losses and are only advantageous if the heat transfer in the jacket can be significantly increased by increasing the heat transfer from the inside to the outside. This is the case if the heat transfer in the vessel and in the jacket are of the same order of magnitude. If the heat balance is well balanced, the pressure loss in the outer jacket is decisive for energetically efficient heating or cooling of a stirred vessel. The pressure loss in the WTP depends on the selected welding circuit grid and the expansion. The design of the inlet and outlet nozzles into the WTP interior and the connection of different WTP spaces are essential. With regard to the design of inlet geometries, LOB has tested numerous designs, which have also led to patented solutions such as ring pipes and endless WTP. With conventional vessels or pipelines, complex geometries, such as support claws or support rings and nozzles on agitator vessels, can only be realized with considerable design effort and high costs. With the LOB WTP System®, however, even complicated vessel geometries can be efficiently tempered.

Testrun

We can deliver all Agitator vessels including Testrun and CE-certificate of the machine.