WTP-Pipelines

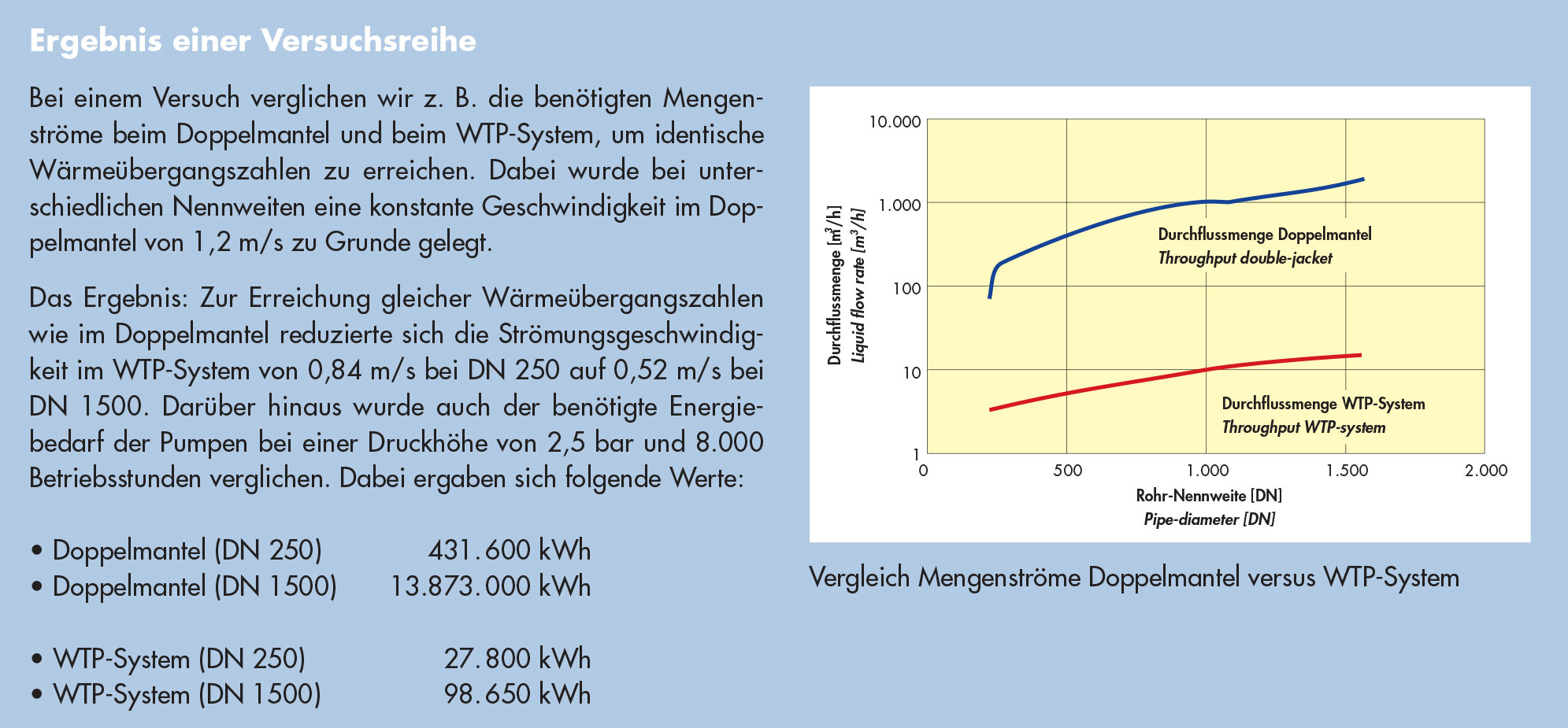

After LOB’s highly successful introduction of the WTP-system® (heat exchanging plates) as an economical alternative of tempering pressure vessels, numerous tests and experiments have demonstrated the capability of this technology to heat double-jacket pipelines more efficiently.

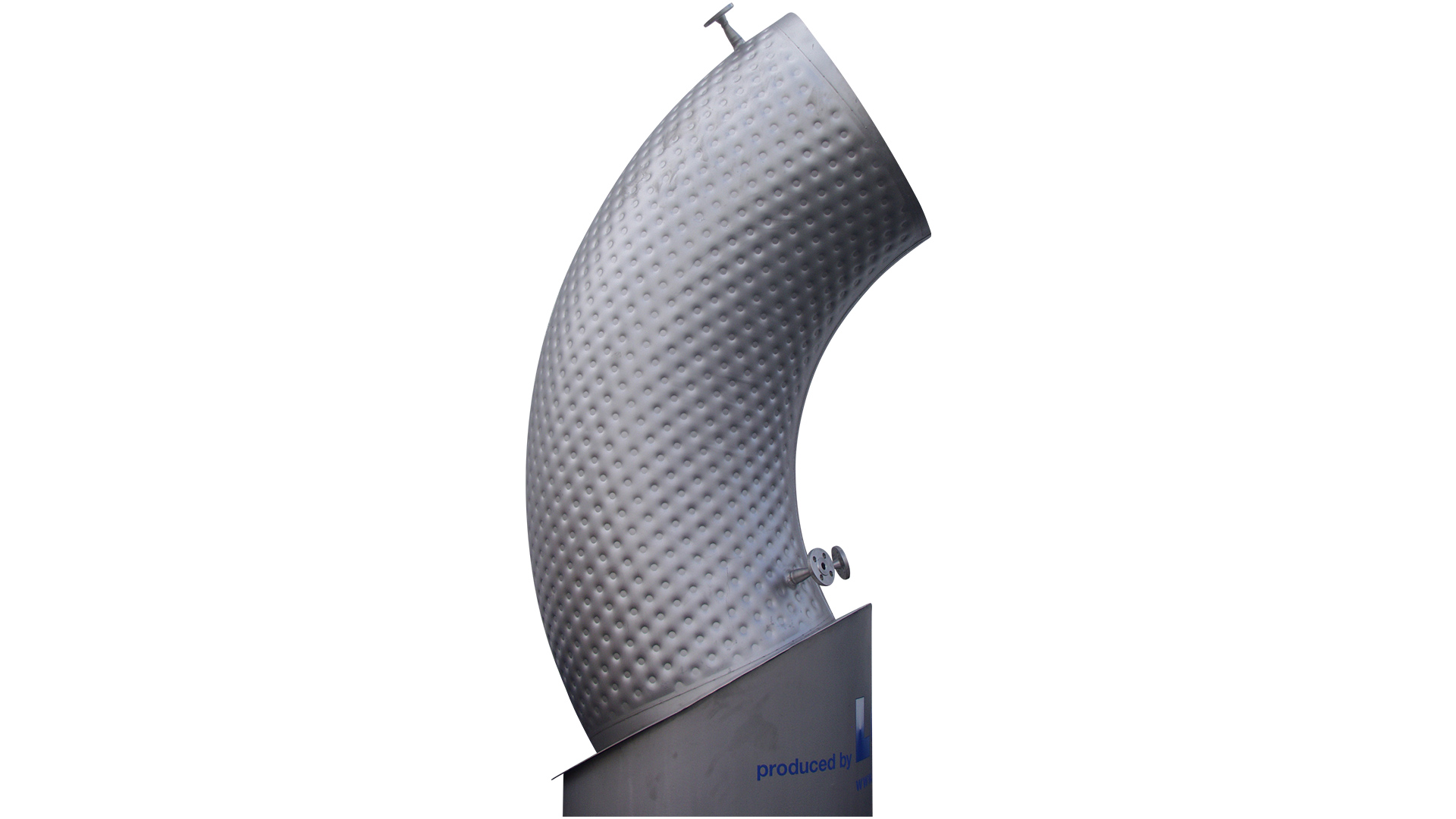

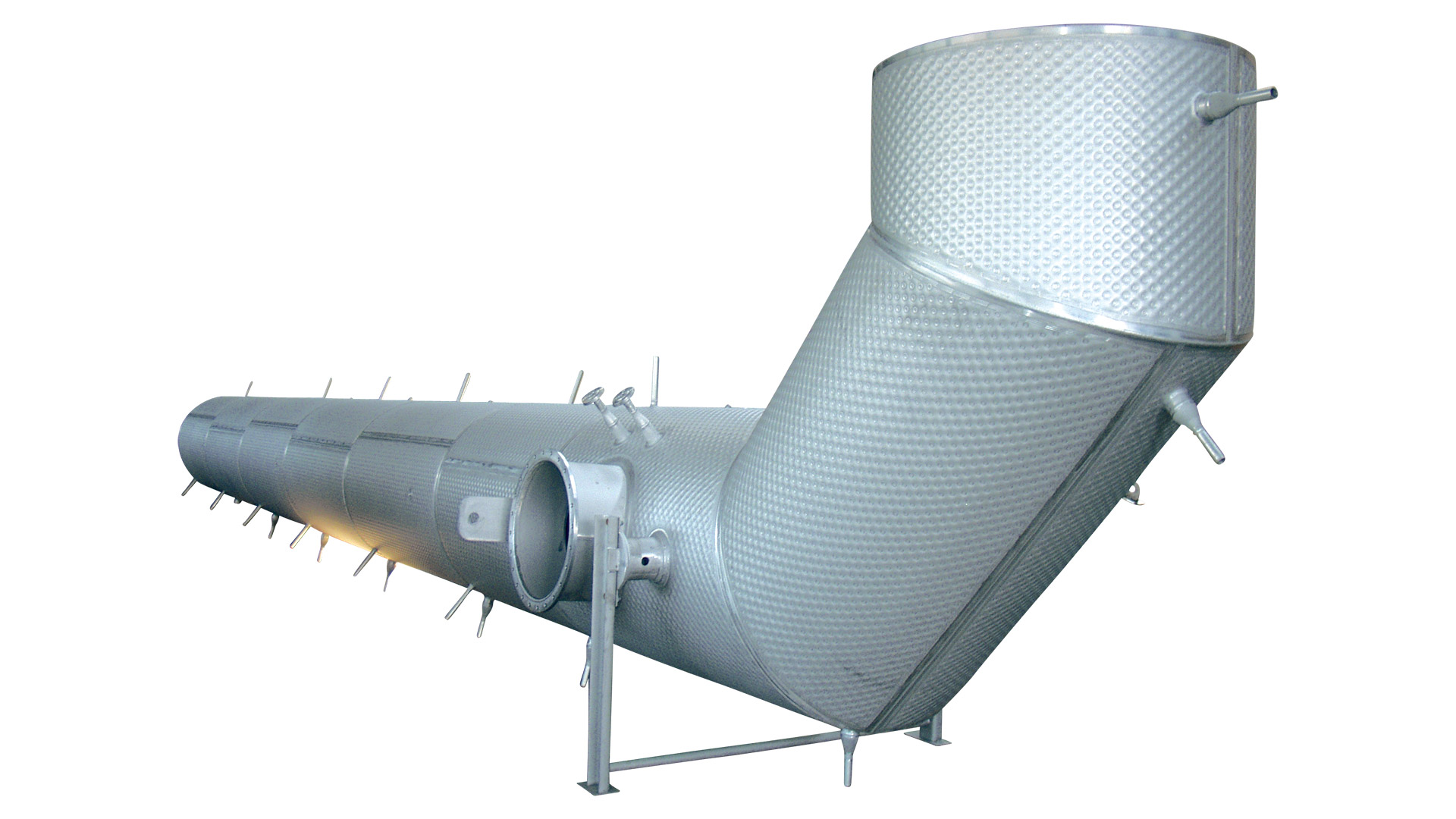

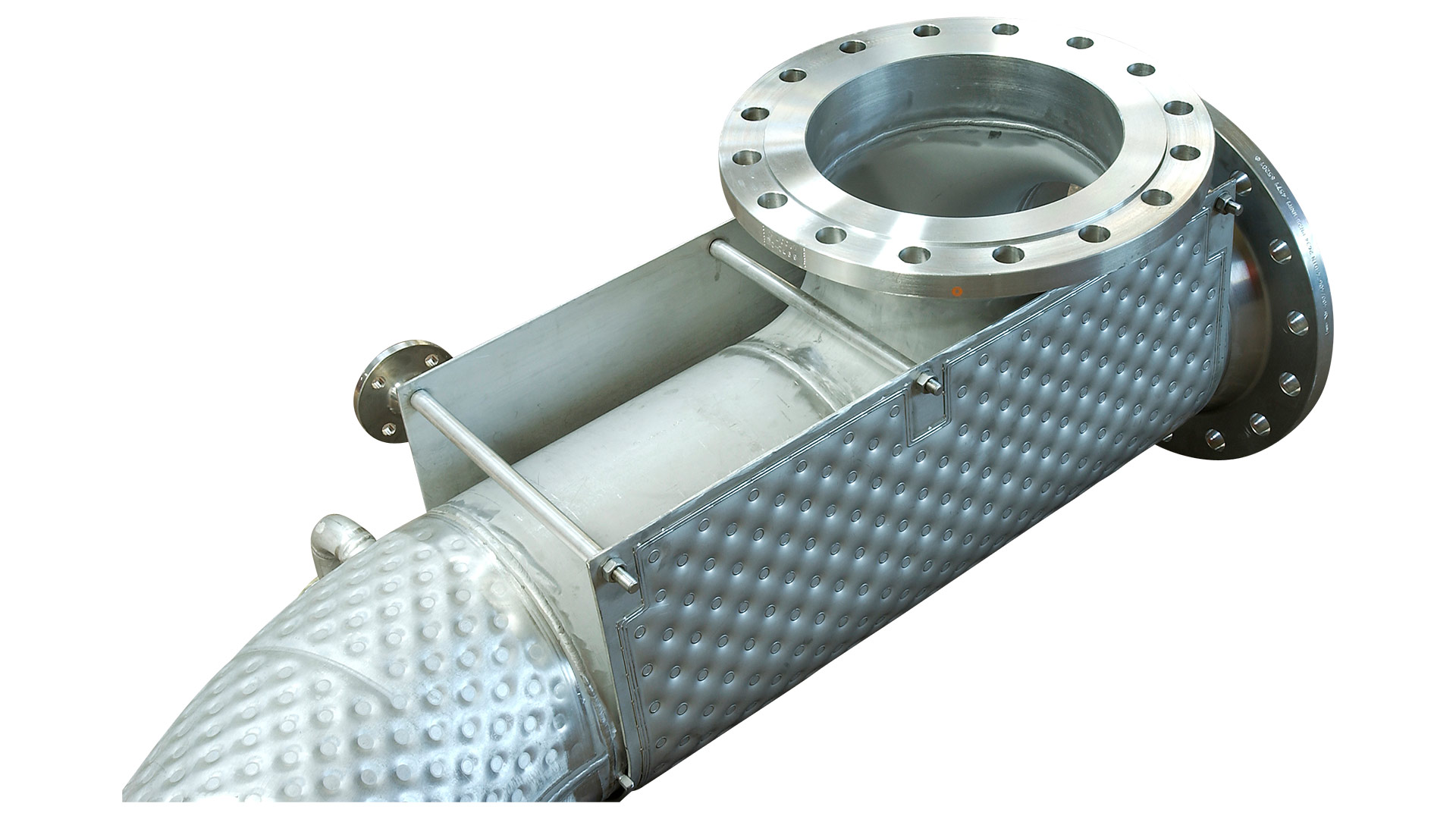

This system can be applied to almost every pipe dimension. Even parts like pipe bends can be equipped, these can either be designed with 2 half-shells or as segment pipe bends. The flow of the service medium is crucial when designing the WTP system.

The arrangement of the pipeline during operation must be taken into account. Each pipeline is specially designed for its specific location during operation. Both heating and cooling medium, whether liquid or gaseous, can be used as service medium.

The optimal positioning and design of the inlet and outlet nozzles is designed in close contact with our customers and their requirements for heat transfer and pressure loss. Free areas, for nozzles, that lead into the inside of the pipeline, or brackets, are planned into the top plate of the WTP system and the service medium is routed around these areas. This leads to a higher heat transfer area compared to a double jacket. Tension, which arises from the different dimensions of such nozzles and the double jacket, are also absorbed by the free areas in the top plate.