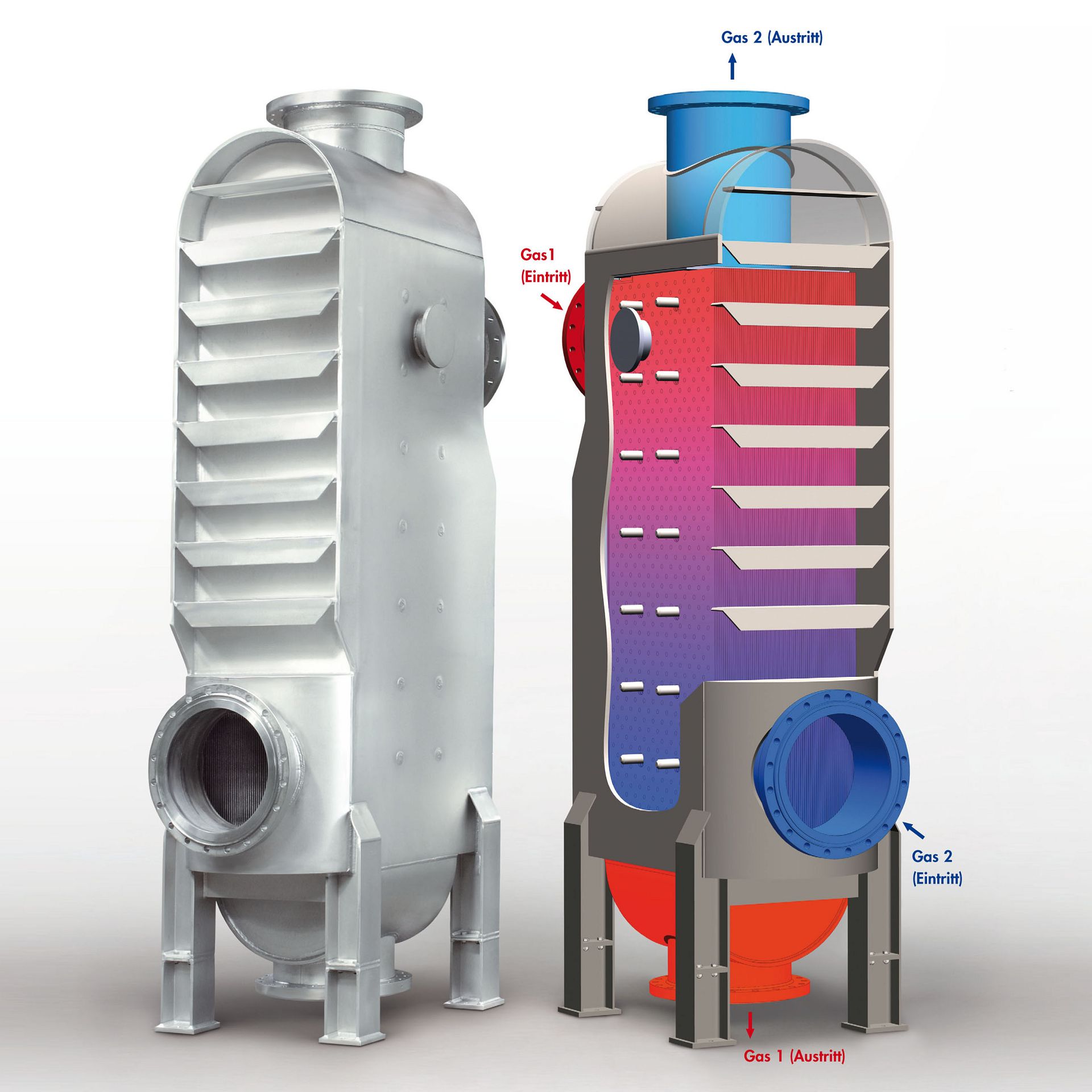

Gas-Gas Cross Counterflow WTP-Heat Exchanger

Many chemical processes generate waste heat, which can be economically reused with a WTP-System® based “gas-gas cross countercurrent heat exchanger”. The recuperator developed by LOB makes use of this waste heat even at high internal and external operating overpressures and this with low pressure loss and low total weight. Process engineering processes often run under high pressure and high temperature. In order to avoid additional energy, which is generated by the use of compressors, it is necessary that heat exchangers on both sides cause the lowest possible pressure loss. Where space is limited, the weight and the enclosed space of the heat exchanger should be kept to a minimum.

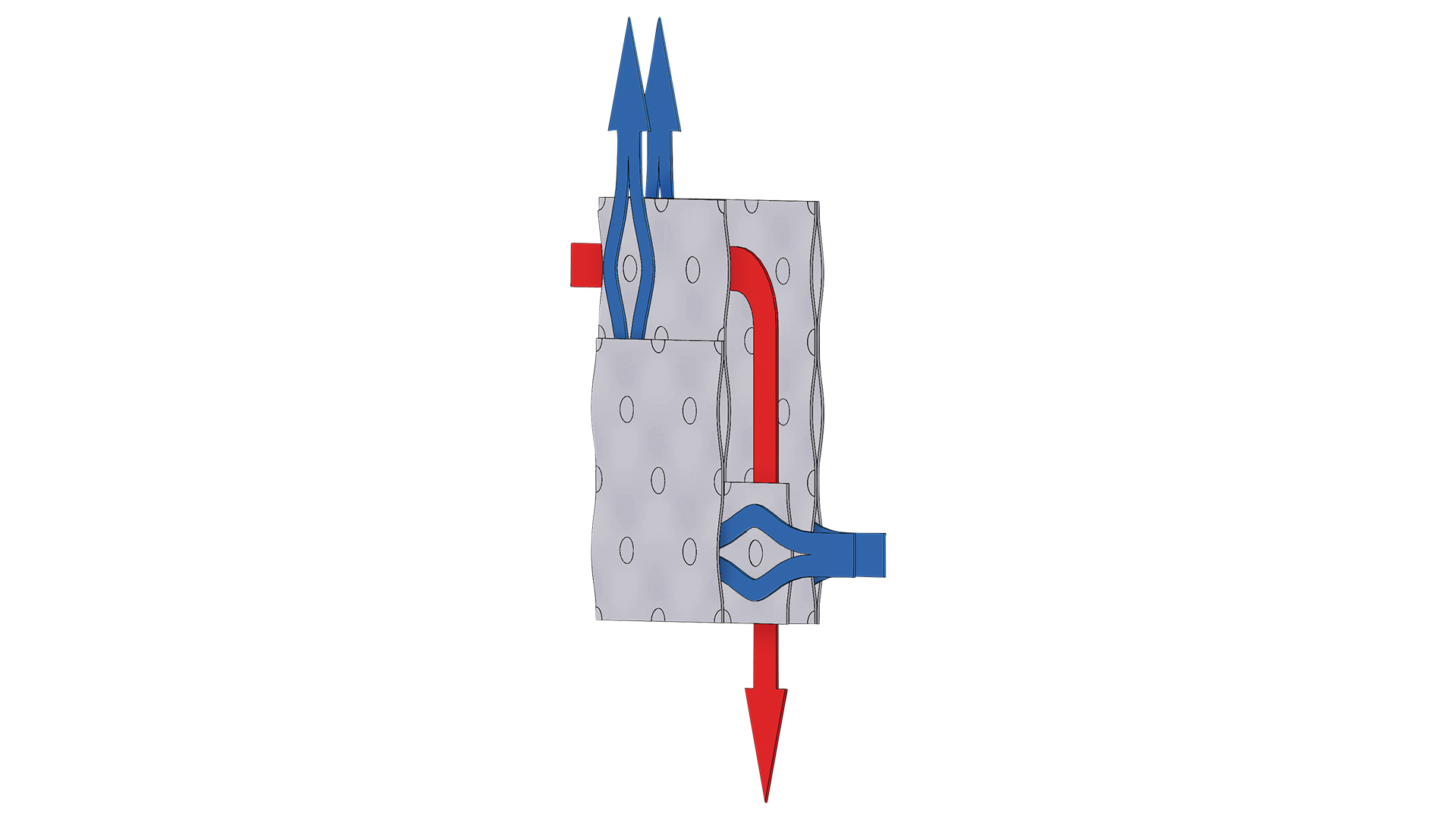

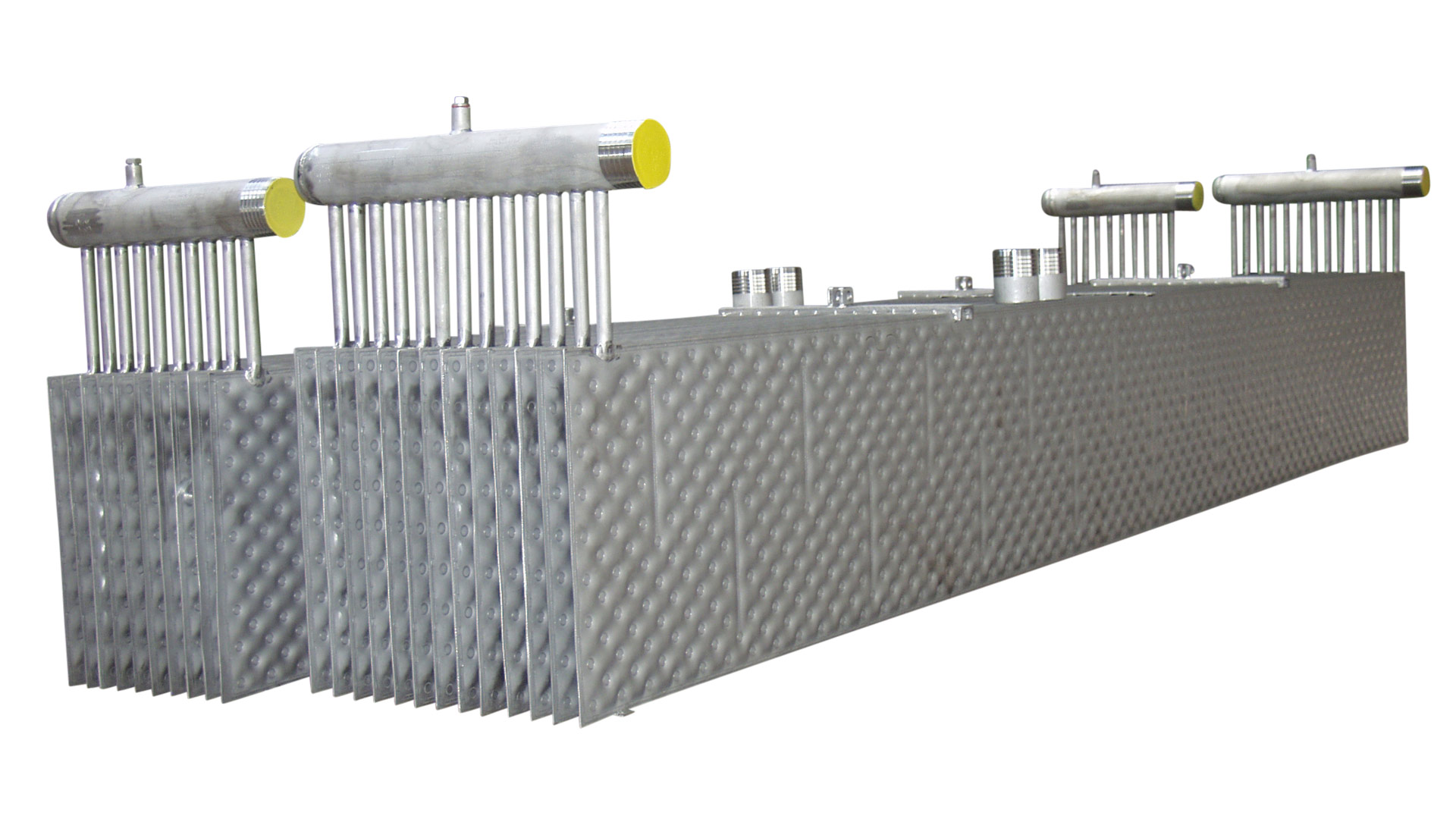

LOB’s newly developed gas-gas heat exchanger with WTP-System® (heat exchanger plate system) meets these requirements. Firstly, a very compact design is achieved by the narrow gaps between the plates and the low cushion heights of the laser-welded heat exchanger plates. This leads to a very low weight and compact dimensions. In addition, we have succeeded in designing the operating overpressure of the cross cooler housing and in the WTP plate package to pressures of > 10 bar through constructive measures – and this with manageable wall thicknesses. The inner sides of the WTP plates are designed in such a way that the pressure can be absorbed depending on the selected welding circuit grid. The pressure around the WTP plates and on the housing wall is absorbed by connecting anchor rods which are guided through the plates and welded to the outer walls.

Since the temperature during start-up and when restarting after a standstill increases relatively abruptly due to the supply of flue gases, LOB has designed the gas-gas cross-countercurrent heat exchanger in such a way that the resulting expansions can be compensated. This avoids thermal stresses between the initially still cold housing and the rapidly heated plate pack. Due to a special way of gas entry into the WTP plates, the resulting pressure loss is significantly lower than with a comparable shell-and-tube heat exchanger. In the recuperative gas-gas heat exchanger the colder flue gas is fed into the WTP plates because of the lower gas volume due to the temperature, while the hotter flue gas is fed between the plates. The expansion of the plates or the plate spacer can be selected in such a way that the gas velocities on the cold or warm side are matched to each other.