WTP-Plate Heat Exchanger

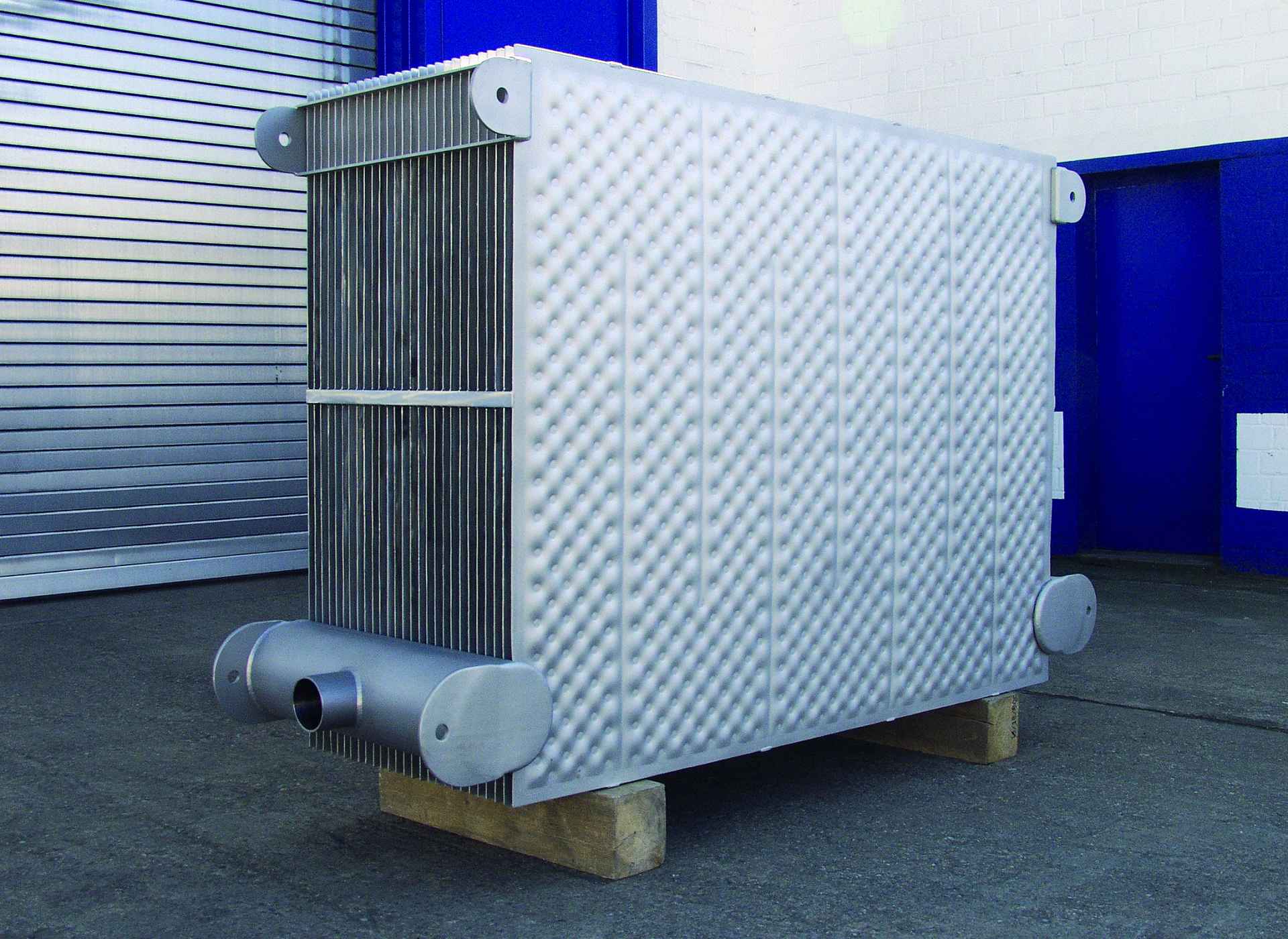

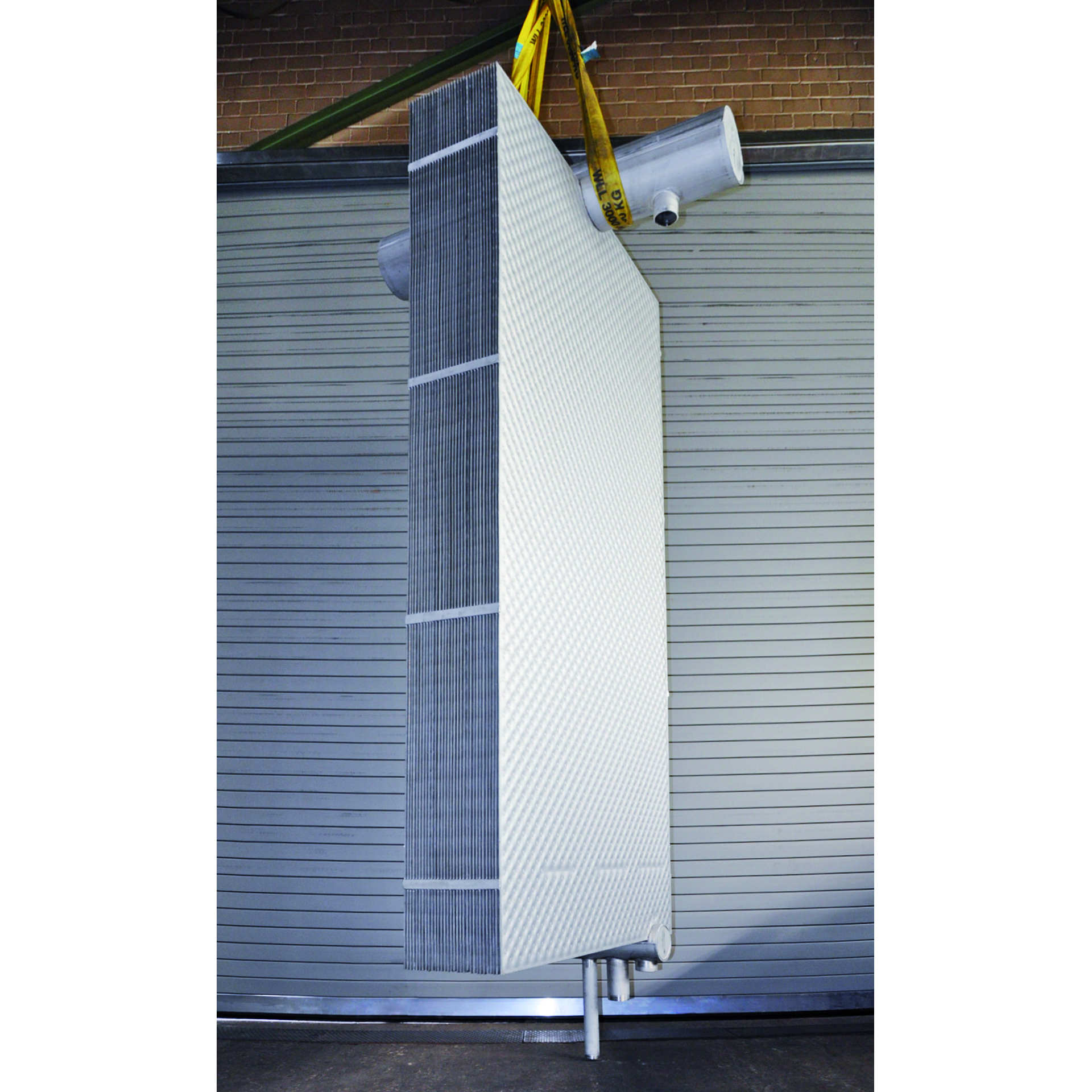

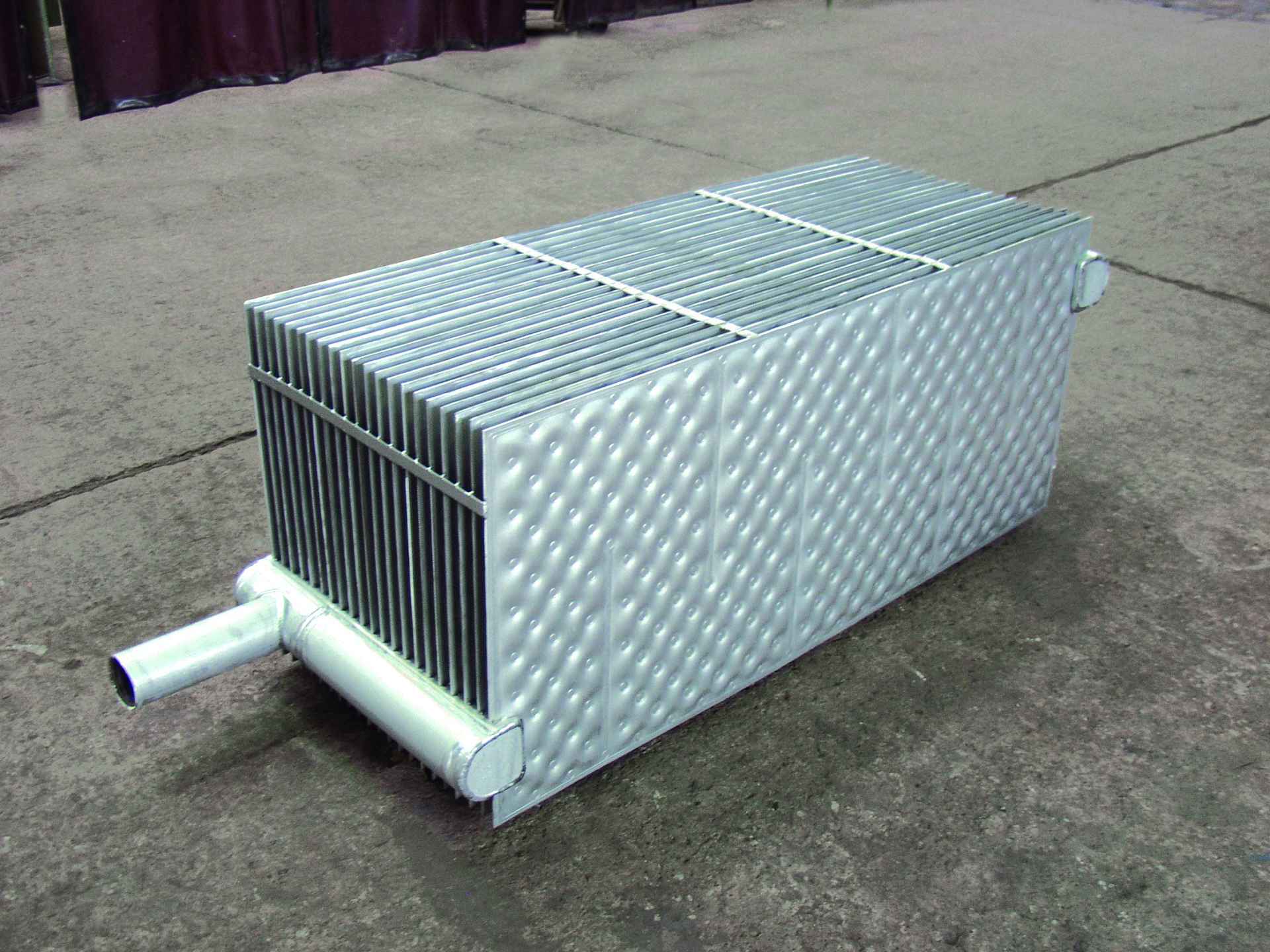

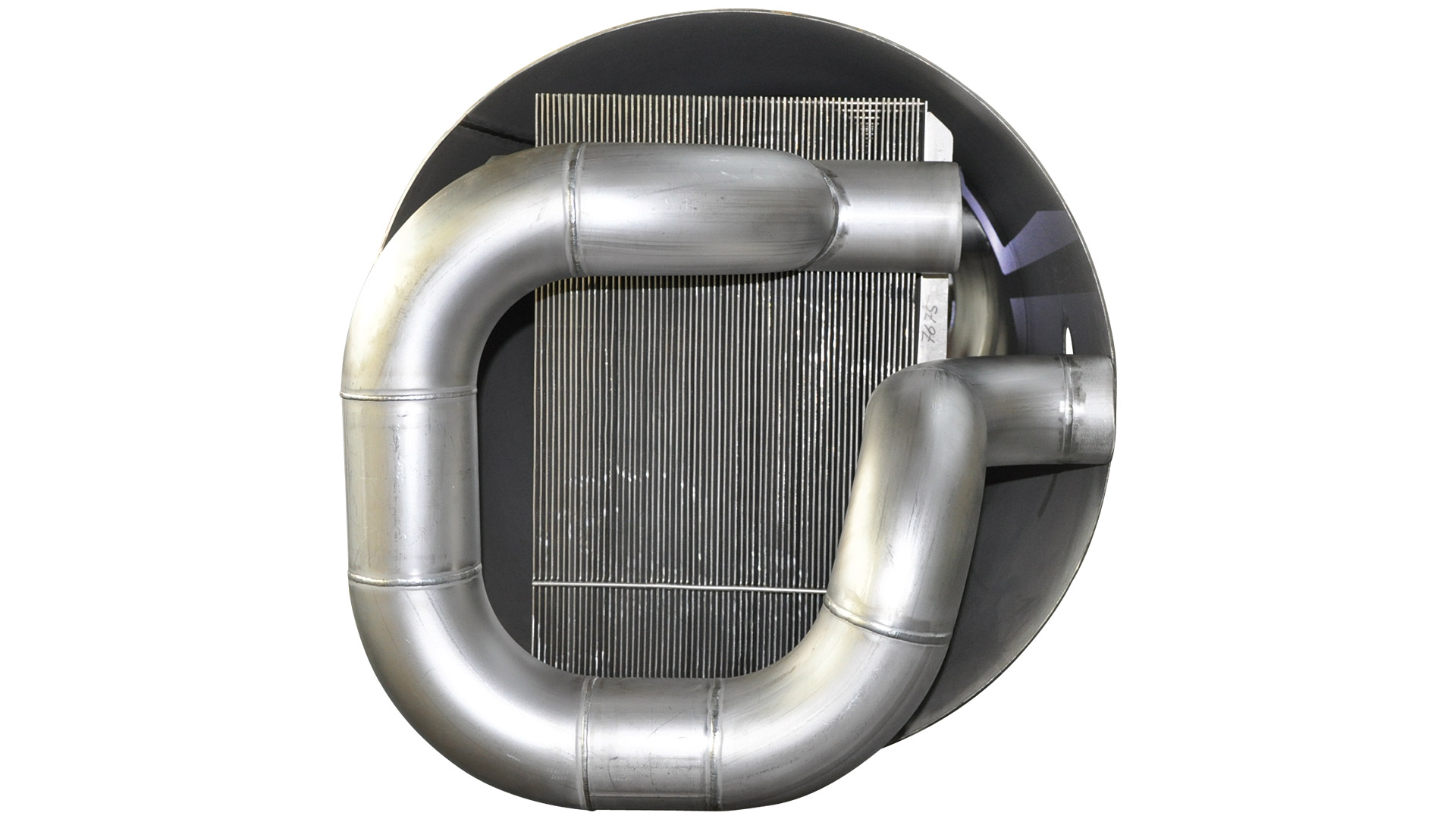

WTP-Plate heat exchanger consist of two sheets of the same wall thickness. These sheets are connected by laser spot welding, in different patterns depending on the heat transfer requirements. All around the edge of the plates, double weld seams form the boundary of the inner product flow. WTP-Plate Heat Exchangers have minimal pressure loss compared to Tube Bundle Heat Exchangers.

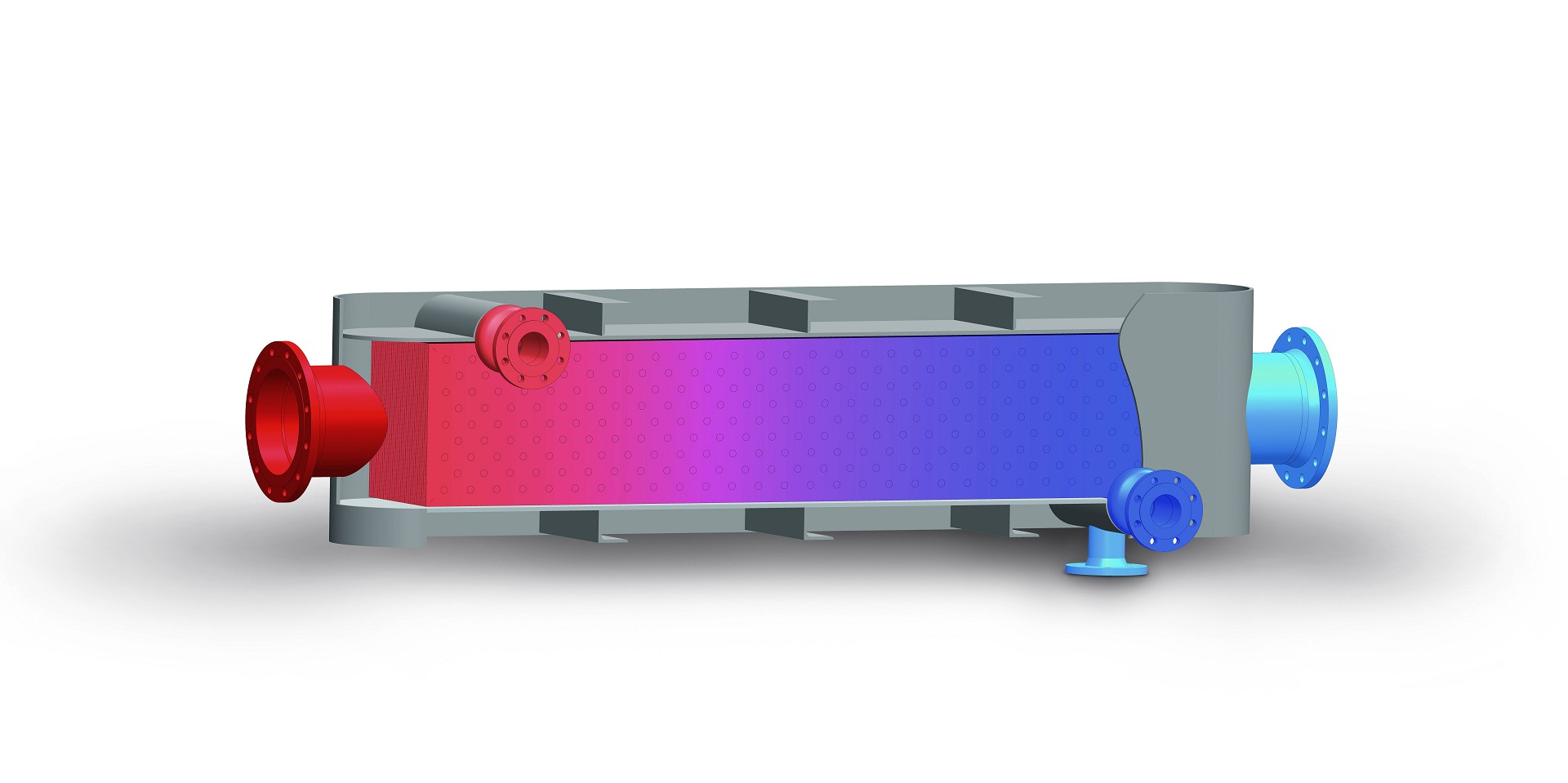

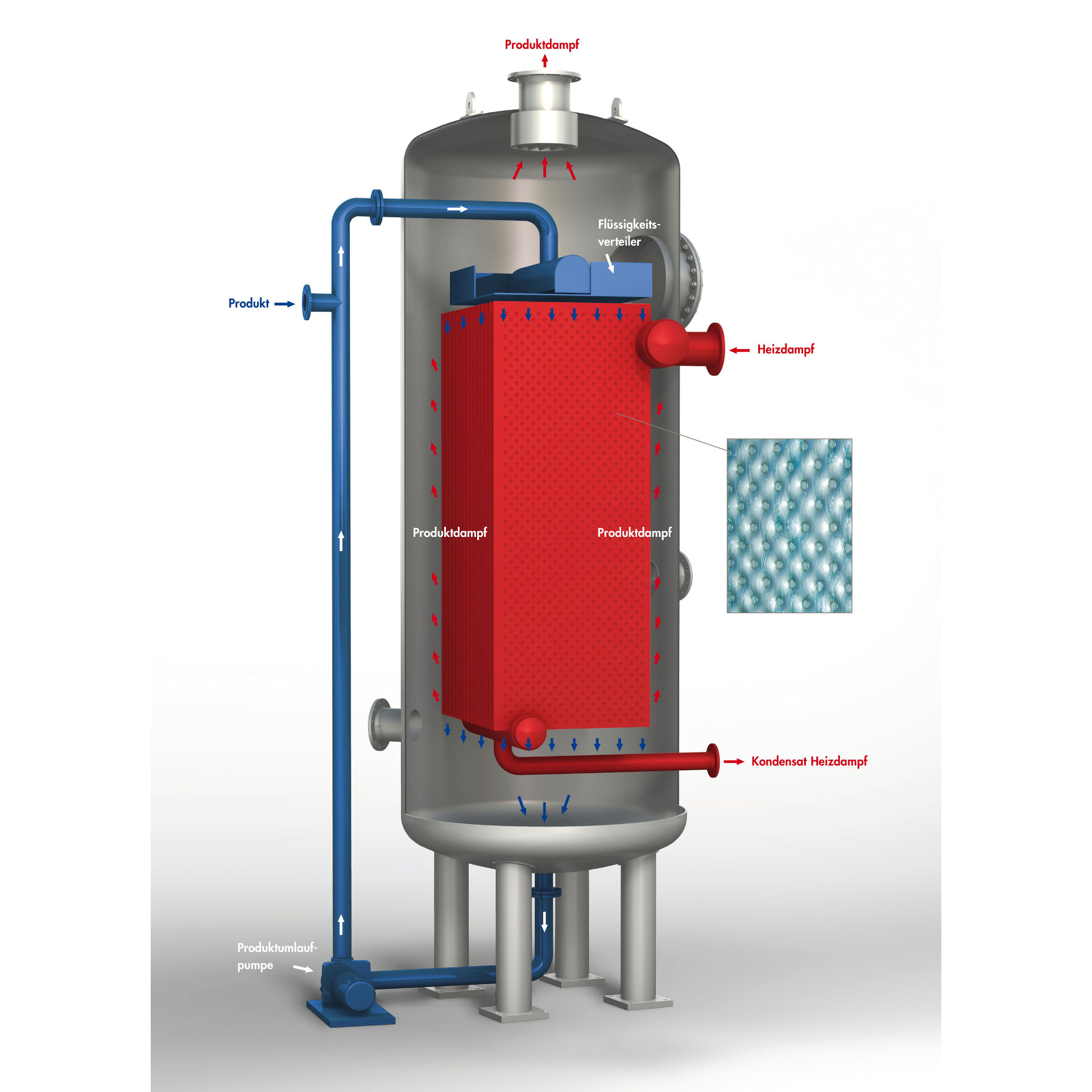

In the chemical industry, processes are used for the separation of liquid mixtures in which the desired components with corresponding concentrations are produced by evaporation with subsequent condensation. For this purpose, a vapor mixture is first generated at the lower end of a column, often several meters high, which then rises against a liquid in the column column, accumulates and is liquefied again in a condenser at the top of the column. Since the condenser is located directly at the top of the column, it is also called the head condenser.

The liquid from the top condenser is either directed downwards in countercurrent to the vapor mixture for further amplification or is drawn off as a finished product. When head condensers are installed at the end of a high column, their weight and volume should be kept to a minimum.